Click on the follow link to find out more information: https://www.sdindustrialfurnace.com/annealing-furnace/

Company Info

- Company Name: Zhejiang Shangding Industrial Furnace Co., Ltd

- Representative: Ye Yu Fang

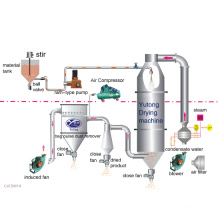

- Product/Service: Heat Treatment Furnace , Hardening Furnace , Annealing Furnace , Electric Furnace , Mechanical Equipment , Tempering Furnace

- Capital (Million US $): 10000000RMB

- Year Established: 2011

- Total Annual Sales Volume (Million US $): US$2.5 Million - US$5 Million

- Export Percentage: 11% - 20%

- Total Annual Purchase Volume (Million US $): US$1 Million - US$2.5 Million

- No. of Production Lines: 3

- No. of R&D Staff: 5 -10 People

- No. of QC Staff: Fewer than 5 People

- OEM Services Provided: yes

- Factory Size (Sq.meters): 10,000-30,000 square meters

- Factory Location: Industrial concentration area of Lincheng Town, Changxing County

- Contact Person: Mr. yehuajian

- Tel: 86--18367270960

Premium Related Products

Hot Products

High quality hotel restaurant Chinese traditional porcelain soup bowl tureenChinese traditional tri-function porcelain chopstick holder for restaurant hotel2015 New Design diamond shape soup pasta plate with elegant designPT-LD-0102 small porcelain spoonspecial moon shape ceramic platesCeramic plate dinnerware Rock grain platehotel ocean line fashion elegance white porcelain ashtray pt-t0535new square Dinner Plates for Restaurant with Excellent Price salad plateporcelain heart shaped plate,porcelain soup plates,daily use white porcelain heart shaped plates for hotelporcelain heart shaped plate,porcelain salad bowl,daily use white porcelain heart shaped bowl for hotel2015 new product OEM ceramic oval plates, china factory direct restaurant oval dinner plateWholesale hot sale luxury factory price high quality wholesale oval fish plateP&T chaozhou factory plates, wholesale price, ceramics dinnerwareFor Wedding 2 Tie White Ceramic Cake Standfactory flower design ceramic coffee mug,hot sale ceramic mug,milk cupP&T porcelain coffee cups and saucers, colorful decal cups and saucers